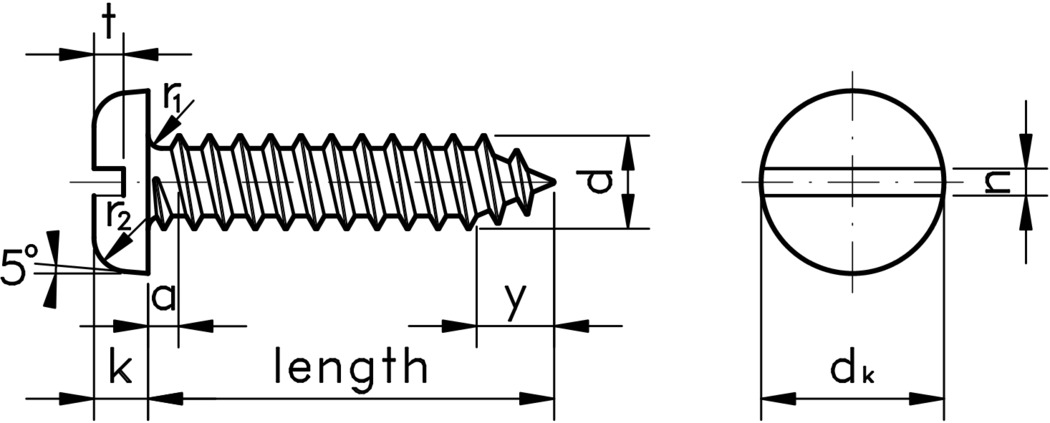

DIN 7971 - Slotted Pan Self Tapping Screws Type C

This product guide contains the specification for slotted pan self tapping screws, a range of standard parts available from Westfield Fasteners. The basis of this specification is the DIN standard DIN 7971.

There are many different types of screw that could be defined as 'self tapping', including several more modern designs. The self tapping screws defined here are the long established type adhering to DIN 7971. The same thread forms with differing head types are defined in other standards. These self tapping screws are manufactured in gauge sizes, from number 2 up to number 14, but these sizes are usually stated alongside the millimetre equivalent.

Self tapping screw thread forms have historically been classified in a number of different ways, and can cause some confusion. The DIN 7971 standard defines the thread form featuring spaced threads and a cone or pointed tip that we are concerned with here as a 'Type C'. This thread form is also known as 'Type AB' elsewhere. These type definitions help to differentiate these cone pointed tapping screws from the square ended or dog point 'Type F' (also known as 'Type B' or 'Type BZ', depending on who you ask).