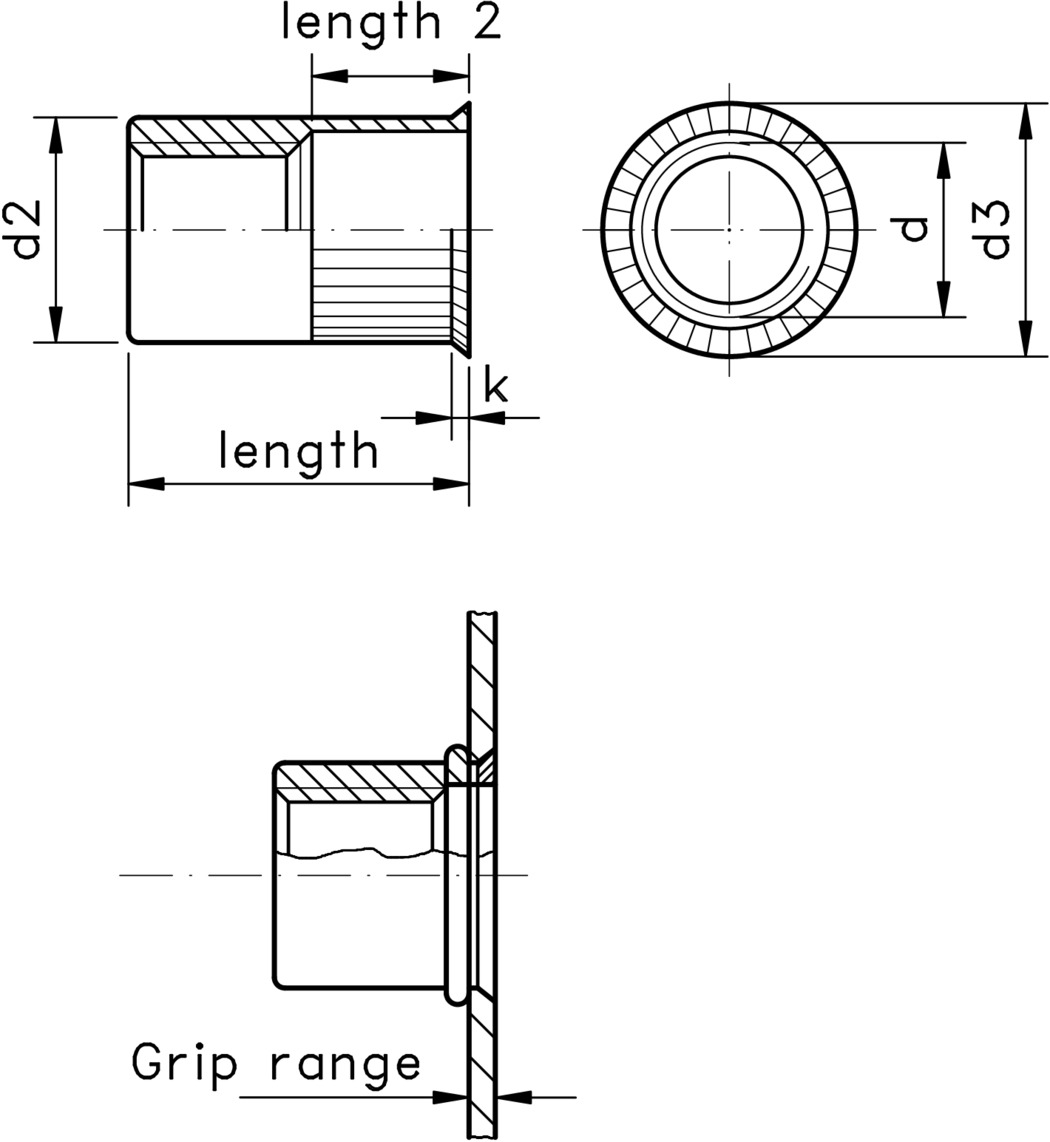

Rivet Nuts - Reduced Countersunk Head with Knurled Shank, Open Type

This product guide contains the specification for blind rivet nuts with a small countersunk head, round knurled shank and an open end. These are a stock item available from Westfield Fasteners.

Rivet nuts are installed by inserting the rivet nuts into the correctly sized and shaped hole within the sheet material. The rivet nut is compressed using a pneumatic powered or hand rivet tool, gripping it firmly to the sheet materials.This causes the rivet nuts to compress to form a collar on the blind side of the sheet material, this prevents the nut from being pulled back through the hole and fixes it securely to the sheet material. Like blind rivets, rivet nuts do not require access to the back of the material, so it can be used in application where there is no access to the back of the sheet materials. Features like knurling or the hexagonal shaped shank helps prevent the rivet nut from turning and loosening.

Small countersunk head with a round knurled shank rivet nuts are a specialist version of the countersunk head rivet nuts, a less commonly required type of rivet nut. With their reduced head height, smaller than the full countersunk rivet nuts, they give an almost flush finish where a non-interference fit is not critical. The small countersunk height is ideal for very thin gauge sheet materials, or when clamping thin single sheet materials, or when the material is not thick enough for the countersunk head to be used. This particular type of rivet nut has an open end enabling longer sized bolts to be fitted, which offers higher vibration resistance.

The knurling and round shank of these reduced countersunk head rivet nuts help to grip the adjoining surface, and can be used in a multitude of industries such as aerospace, automotive, rail, HVAC, white goods, electronics, DIY and general engineering.

Table 1 below gives dimensions for stainless steel variants in available sizes from M3 to M12, along with information on sheet material thickness, pre-drilled hole sizes and tensile strengths. Table 2 provides similar information for zinc plated steel items.

Please note that head dimensions and overall length may vary between batches, any specifications given in the tables below are guide values only and should be checked by testing.