DIN 6799 - E Clips

This product guide contains the specification for E Clips, a type of retaining washer for shafts. E Clips are standard parts available from Westfield Fasteners. The basis of this specification is the DIN standard DIN 6799.

E clips are a type of circlip, and are designed for fitment into a mating groove on a shaft or tube. E clips can be used in pairs to help locate other components in place and prevent them from moving along the shaft when the assembly is turning or spinning. As the E clip is pressed into the groove on fitting, it will spread open and grip the shaft between its three points. E-clips are also known as E type circlips, or E rings. E Clips are sized by the diameter of shaft or groove that they are designed to fit.

E Clips are easy to install, available in many sizes, and can be removed with needle-nose pliers and be reused. They're used in a wide range of applications, such as differentials, gear boxes and printing equipment.

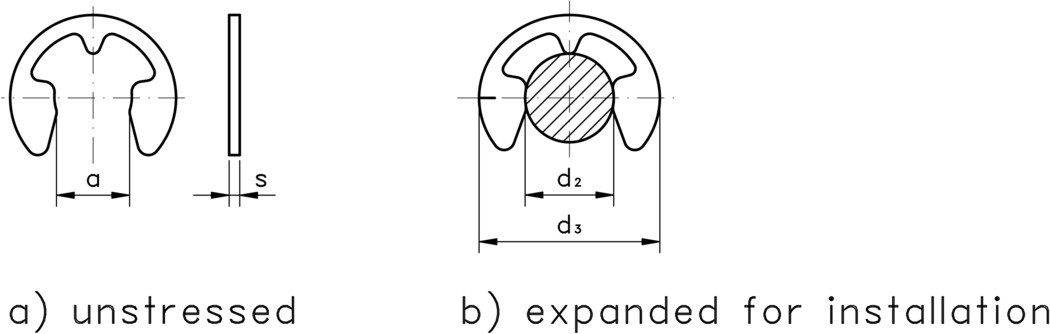

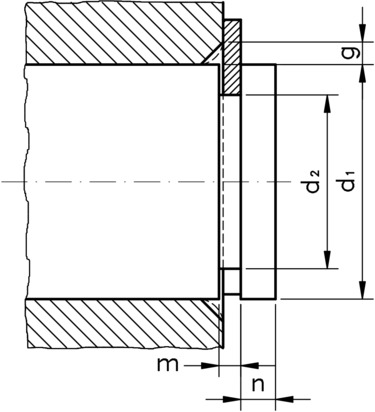

DIN 6799 is the standard specification for manufacturing retaining washers for shafts, more commonly known as E clips, and details the requirements for their use in the axial retention of components on shafts. E Clips are designed to be inserted radially into a mating groove, grip the shaft using their inherent spring tension. Figure 1 and table 1 below define the overall dimensions and tolerances of these E Clips. Table 2 provides some supplementary design information.

The standard states that these clips should conform to the dimensions and tolerances given on the assumption that they are in an uncoated condition. DIN 6799 mentions manufacture in carbon steel and stainless steel.

Figure 1: E Clip

Key to Figure 1

- opening width of the unstressed retaining washer (a)

- shaft diameter (d1)

- groove diameter: nominal size (d2)

- maximum external diameter when seated in the groove with nominal diameter (d3)

- corner distance (g)

- groove width (m)

- edge margin (n)

- thickness of retaining washer (s)