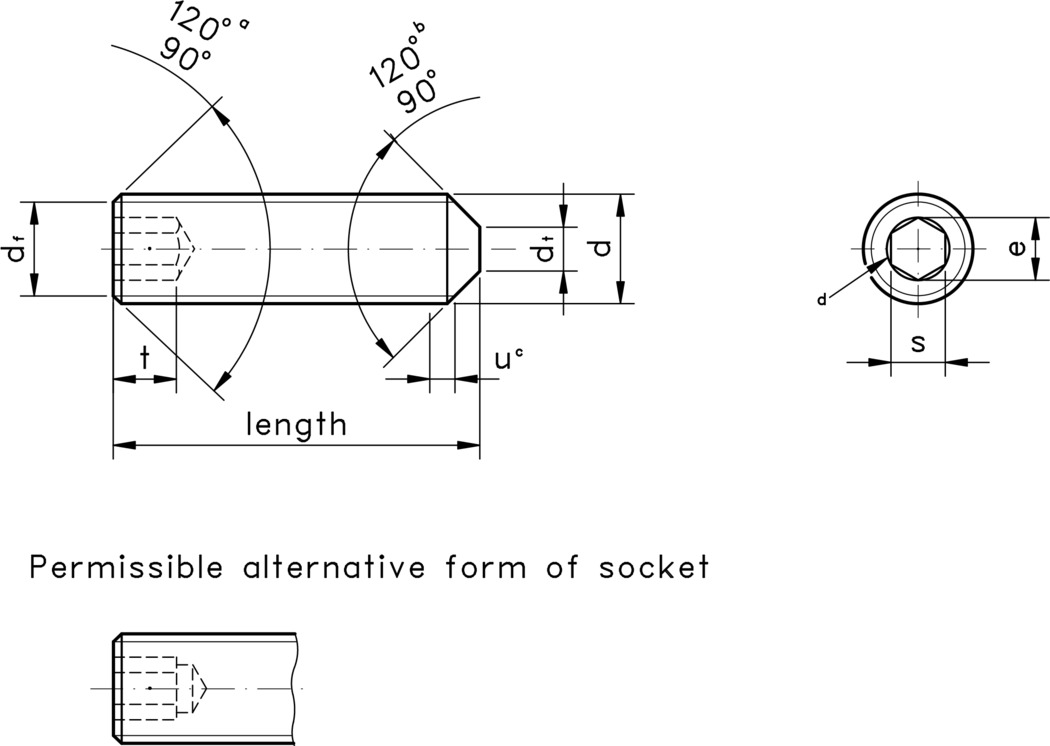

ISO 4027 / DIN 914 - Cone Point Grub Screws

This product guide contains the specification for metric threaded cone point grub screws as available from Westfield Fasteners. The basis of this specification is the ISO standard ISO 4027 and the older DIN 914.

Grub screws in general are graded by hardness rather than by tensile strength. The relevant DIN and ISO standards specify a 45H hardness grade for non stainless steel grub screws and 21H for stainless steel grub screws.

Although the DIN 914 standard has been superceded by ISO 4027, the dimensions are the same and off-the-shelf parts could be marked with either standard.