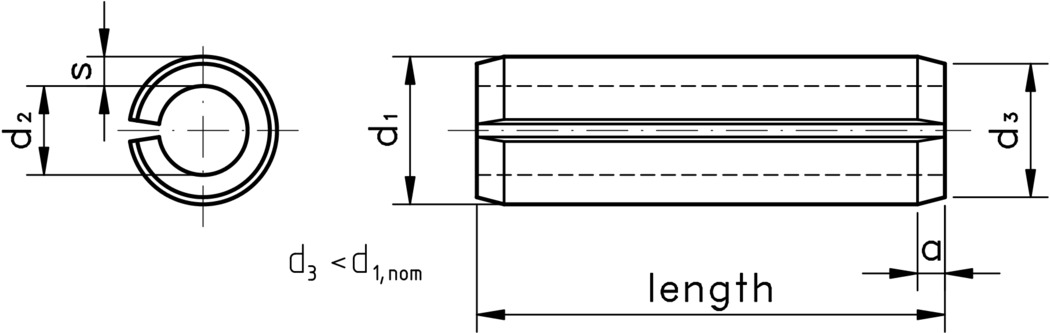

ISO 8752 / DIN 1481 - Slotted Spring Pins (Roll Pins), Heavy Duty Type

This product guide contains the specification for metric sized slotted spring pins, heavy duty type, as available from Westfield Fasteners. The basis of this specification is the ISO standard ISO 8752 and the older DIN 1481.

Slotted roll pins are also known as slotted spring pins, tension pins, split dowel pins and hollow spring pins. Slotted roll pins are generally used for locating two parts accurately. This particular type and are designed for more heavy duty use than other types of tension pin.

Table 1 below defines the overall dimensions and tolerances of this pin type. Minimum shear strength values given in this table are applicable to steel and martensitic stainless steels only; figures for austenitic stainless steels are not given, which unfortunately includes 301 grade stainless steel, a material choice available from Westfield Fasteners for these items.

ISO 8752 supercedes the DIN standard 1481. Parts are interchangable between the two standards except that the option for a chamfer at one end begins at 8mm diamter for the DIN standard, whilst the ISO standard specifies this option from 10mm.