Westfield Fasteners Product Specification:

DIN 7337 - Blind Rivets with Pan or Dome Head

This product guide contains the specification for blind rivets or pop rivets with a pan or dome head as available from Westfield Fasteners. The basis of this specification is the DIN standard DIN 7337.

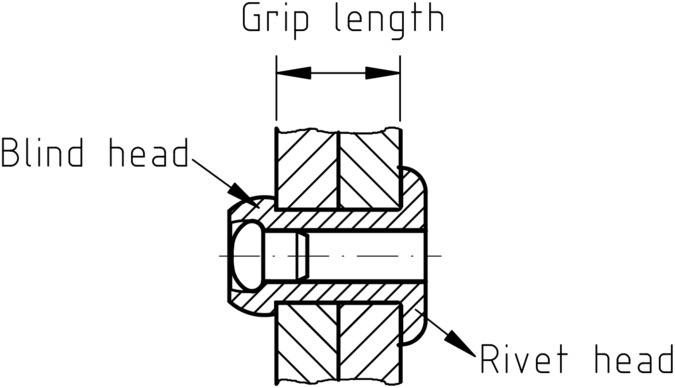

Blind rivets, also known as pop rivets, are an unthreaded fastener. Blind rivets are available in many variations, with differing head types, material combinations and colours. This specification focusses on dome or pan head types, also called a flat head to the DIN standard DIN 7337. Blind rivets create a permanent fixing and can be used when access is only available on one side of the workpiece or joint. The rivet is fixed in place with a rivet gun.

Scope of the DIN standard.

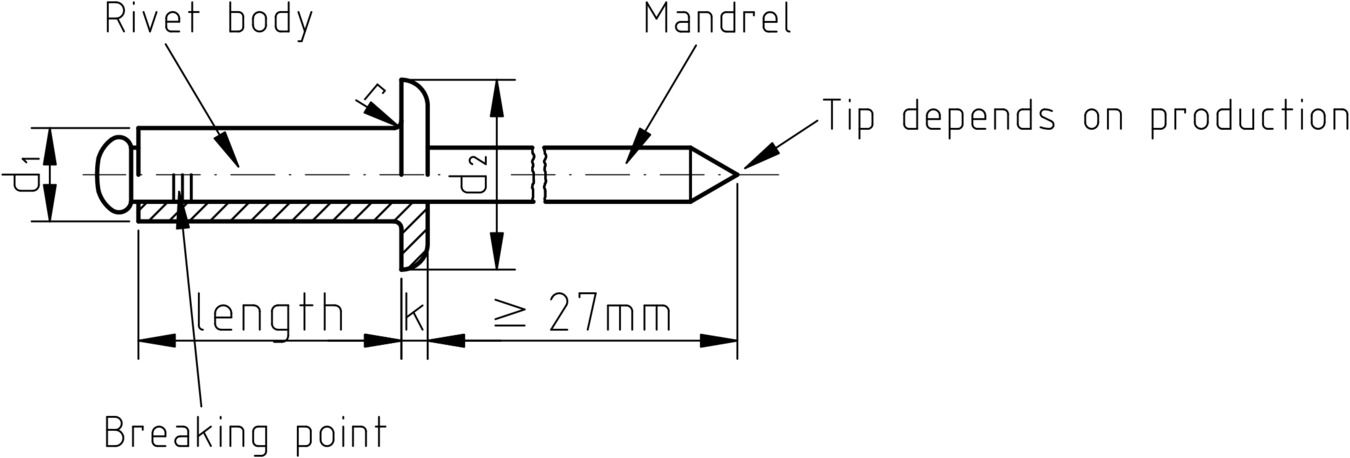

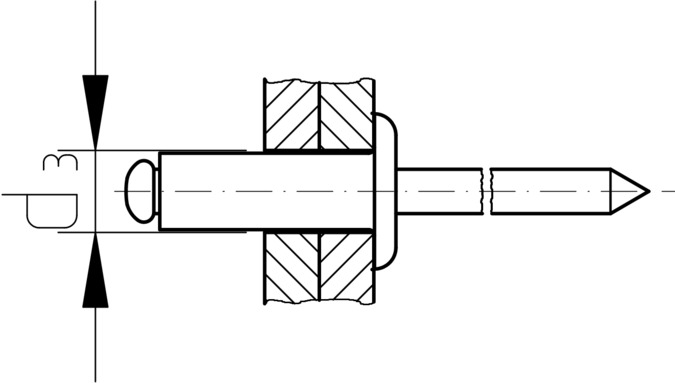

DIN 7337 specifies the dimensions, design, strength and finish of break mandrel blind rivets. Each rivet consists of a rivet body and an integral mandrel, which breaks off during application. This standard covers all the typical head types and material combinations.

The data in the tables below are provided to assist with installation of these blind rivets. Table 1 defines the overall dimensions and tolerances of this fastener type. Tables 2 and 3 offer minimum shear and tensile strengths respectively by material. Table 4 offers a nominal size for the holes to to be used with these rivets. Tables 5, 6, 7 and 8 give grip length ranges for the various size and material combinations available.